Applications

- Industrial Manufacturing: Ideal for storing automotive parts, electronic components, and other manufacturing materials, offering customized storage based on part size, weight, and usage frequency.

- E-commerce Logistics: Helps manage large volumes of goods with efficient categorization for fast picking and delivery, improving order fulfillment speed and customer satisfaction.

- Pharmaceuticals: Ensures safe storage of medicines and medical devices, maintaining strict temperature, humidity, and expiry management standards.

- Food & Beverage: Optimizes food storage with hygiene controls, FIFO principles, and careful planning to reduce food waste and ensure safety.

- Libraries & Archives: Provides organized storage for books, journals, and archives, improving accessibility and security while supporting automation for fast retrieval.

Core functions

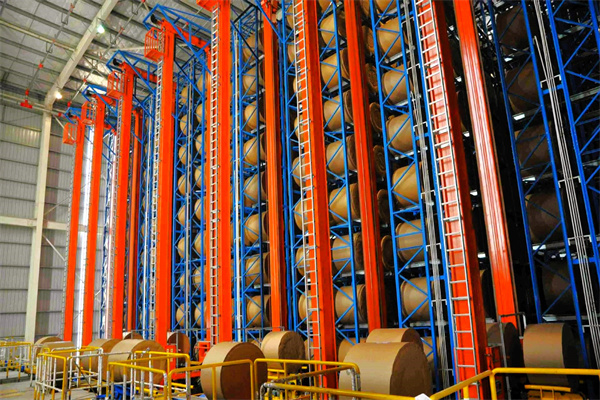

- Automated Storage/Retrieval:Utilizes stackers or robots for automated cargo handling, reducing manual intervention and enhancing efficiency.

- Intelligent Scheduling: Integrates with WMS (Warehouse Management System) and WCS (Warehouse Control System) to optimize inventory management and operational workflows.

- High-Density Storage: Employs multi-tiered dense arrangements, achieving 2-5x higher storage density than traditional racks.

- Dynamic Inventory Counting: Supports RFID or barcode scanning for real-time stock monitoring, reducing error rates.

- Protection: Equipped with anti-collision devices, fire-resistant coatings, and seismic-resistant designs to ensure cargo and operational safety.

Specifications

| Parameter | Specification Range |

| Height | Typically 10-30 meters (customizable based on factory conditions, can exceed 40 meters), must comply with national and industry standards. |

| Rack Depth | Single-depth (single-channel) or double-depth (double-channel), typically 1.2-2.4 meters. |

| Single-layer Load Capacity | Light-duty: 100-500 kg/layer; Medium-duty: 500-2000 kg/layer; Heavy-duty: 2000-5000 kg/layer (pallet-style). |

| Aisle Width | 1.5-2.5 meters (depends on stacker crane or forklift type). |

| Material | Cold-rolled steel, hot-rolled steel, surface rust treatment (e.g., electrostatic spraying). |

| Structure Type | Beam-type, shuttle-type, gravity-type, drive-in, etc.; customizable design available. |

| Control System | Optional PLC or industrial computer control, compatible with ERP/WMS systems. |