Applications

- Continuous Material Transport: Seamlessly transports palletized goods between different stations in production lines or warehouse systems, such as the assembly line for automotive body parts.

- Sorting and Stacking: Automatically sorts goods by order, type, or destination, and stacks them for storage. Commonly used in e-commerce logistics centers and cold chain warehousing.

- Cross-Scenario Adaptability: With modular design, it can flexibly meet the diverse needs of industries such as manufacturing, food processing, and pharmaceuticals, including special environments like high and low temperatures.

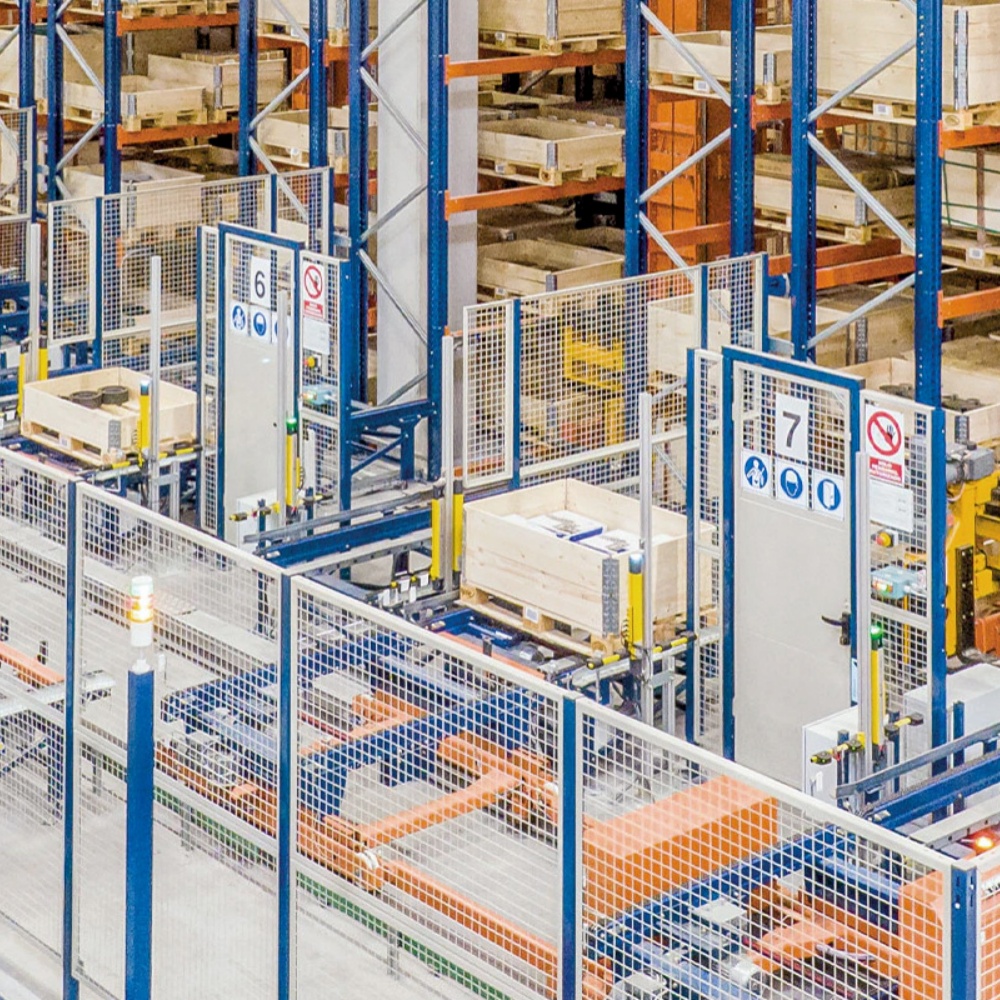

- Space Optimization: Paired with racking systems in vertical warehouses, it improves space utilization, making it ideal for high-density storage scenarios.

Core Features

- Automated Transport and Sorting: Pallets are driven by rollers, chains, or belts, combined with sensors and control systems to ensure precise positioning (within ±5mm). Dynamic path adjustments are supported, and sorting arms or pneumatic devices are integrated for sorting, stacking, and loading tasks.

- Smart Management: Equipped with IoT technology to monitor operational status in real-time, and seamlessly integrates with WMS (Warehouse Management System) or MES (Manufacturing Execution System) to optimize task scheduling. Some advanced models feature AI algorithms for predictive maintenance, reducing downtime.

- Flexible Configuration and Expansion: Can be configured into linear, circular, or telescopic layouts. For instance, non-powered telescopic roller conveyors adapt to varying loading and unloading vehicle lengths, improving efficiency. Custom designs can be incorporated, such as adding lifting, rotating, or transplant modules to meet complex process requirements.

Key Selling Points

- Efficiency and Cost-effectiveness: Increases efficiency by 30%-50% compared to manual handling, significantly reducing labor costs. Standardized pallet reuse (e.g., leasing models) minimizes idle waste and procurement costs.

- High Reliability and Safety: Equipped with emergency stop devices, anti-collision sensors, and self-diagnostic functions to ensure safe human-machine collaboration. The metal frame structure (e.g., carbon steel or stainless steel) provides high load-bearing capacity (up to 2 tons or more), making it suitable for heavy-load scenarios.

- Environmental Adaptability: Designed for low temperatures (-25°C), suitable for cold chain logistics. Moisture-resistant and anti-rust materials meet clean room requirements. Low noise (<75dB) and zero-emission characteristics comply with environmental regulations, making it ideal for indoor operations.

Specifications

| Parameter/Type | Specification Description |

|---|---|

| Load Capacity | Light Duty (0.5-1 ton), Medium Duty (1-2 tons), Heavy Duty (2 tons or more) |

| Drive Mode | Powered (motor-driven), Non-powered (gravity rollers), Hybrid (belt + rollers) |

| Speed | 0.5-2 m/s; high-speed models can reach 3 m/s (e.g., chain conveyor lines) |

| Power and Energy | 380V industrial power or lithium battery; energy-optimized design (20% lower no-load power) |

| Expansion Features | Can integrate lifting positioning, RFID tracking, laser welding modules, etc. |