Applications

Shuttle rack system is a semi-automated high-density storage solutions designed for efficient storage management. Ideal for:

- Cold Chain Warehousing: such as food, medicine and other industries that require low-temperature storage.

- Large-volume single-goods storage: batch goods management, such as beverages, tobacco, chemical raw materials, etc.

- High-density storage requirements: scenarios where warehouse space is limited and space needs to be maximized.

- Automation upgrade: warehouses that want to reduce manual operations and improve efficiency.

Core Features

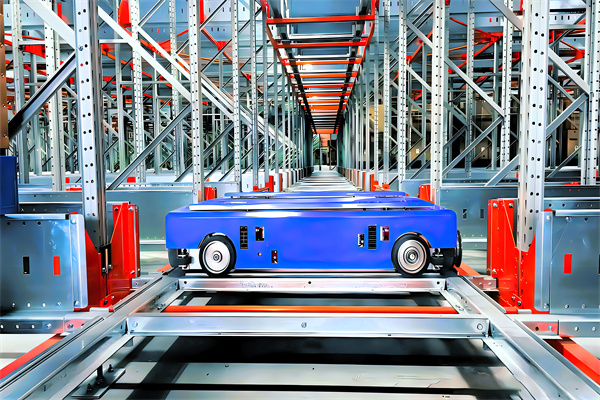

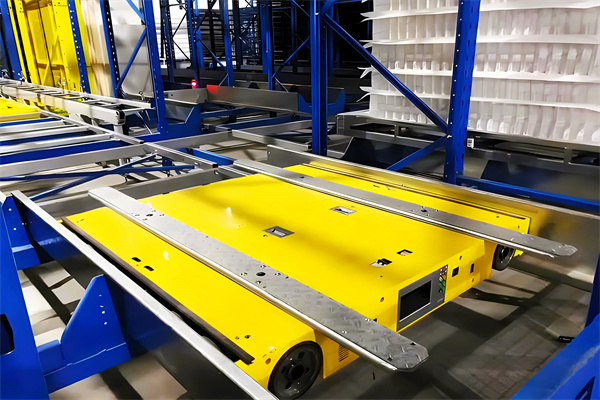

- Automated Handling: Shuttle vehicles autonomously transport pallets, minimizing human intervention.

- High-Density Layout: Increases storage capacity by 30%-50% compared to traditional racks.

- Flexible Access Modes: Supports FIFO (First-In-First-Out) or FILO (First-In-Last-Out) strategies for optimal inventory rotation.

- Real-Time Inventory Control: Integrates with Warehouse Management Systems (WMS) for live tracking and data-driven decisions.

Key Advantages

- Maximize space utilization: through dense storage design, more goods can be stored in a limited warehouse space, reducing warehouse rental costs, especially suitable for enterprises with tight land resources and limited storage space.

- Improve operation efficiency: automated operation reduces dependence on manual labor, and shuttles quickly access goods, shortening operation time.

- Safety & Durability: Heavy-duty steel construction and collision-resistant designs ensure reliable operation, reducing workplace accidents.

- Scalability: Modular systems allow easy expansion (e.g., adding racks or shuttles) to meet growing demands.

Specifications

- Rack Height: 6-30 meters (customizable).

- Shuttle Capacity: 500-1,500 kg (configurable).

- Material: High-strength steel for long-term stability.

- Control Integration: Compatible with WMS/WCS platforms.

- Power: Battery-operated shuttles with 8-12 hours runtime.

- Speed: 1-1.5 m/s for rapid transfers.

- Temperature Range: Standard (ambient) or cold-chain models (-25°C to -30°C).

Applicable Scenarios

- Food & Beverage: Manages perishables with FIFO/FILO modes to ensure freshness (e.g., canned drinks, packaged foods).

- Pharmaceuticals: Complies with strict storage standards for drugs/medical devices, enabling precise tracking.

- E-Commerce Logistics: Handles high-SKU volumes and rapid order fulfillment, boosting space utilization.

- Auto Parts: Stores diverse components (engine parts, body panels) for streamlined supply chain management.

- Cold Storage Logistics: Operates reliably in freezers, reducing manual labor in low-temperature environments.