Application of Shuttle Vehicles

- High-Density Warehousing:Automated pallet storage/retrieval in compact racking systems (space utilization 5-6× higher than conventional racks), ideal for cold storage and urban logistics centers.

- Manufacturing Material Handling:JIT (Just-in-Time) supply of raw materials to automotive/electronics production lines, reducing WIP (Work-in-Progress) inventory by 25-40%.

- Pharma & Cold Chain Logistics:GMP-compliant transport in -25℃ environments with sealed stainless steel bodies to prevent contamination.

- E-commerce Order Fulfillment:Integrated with WMS for 30%+ peak efficiency improvement in SKU sorting and cross-docking.

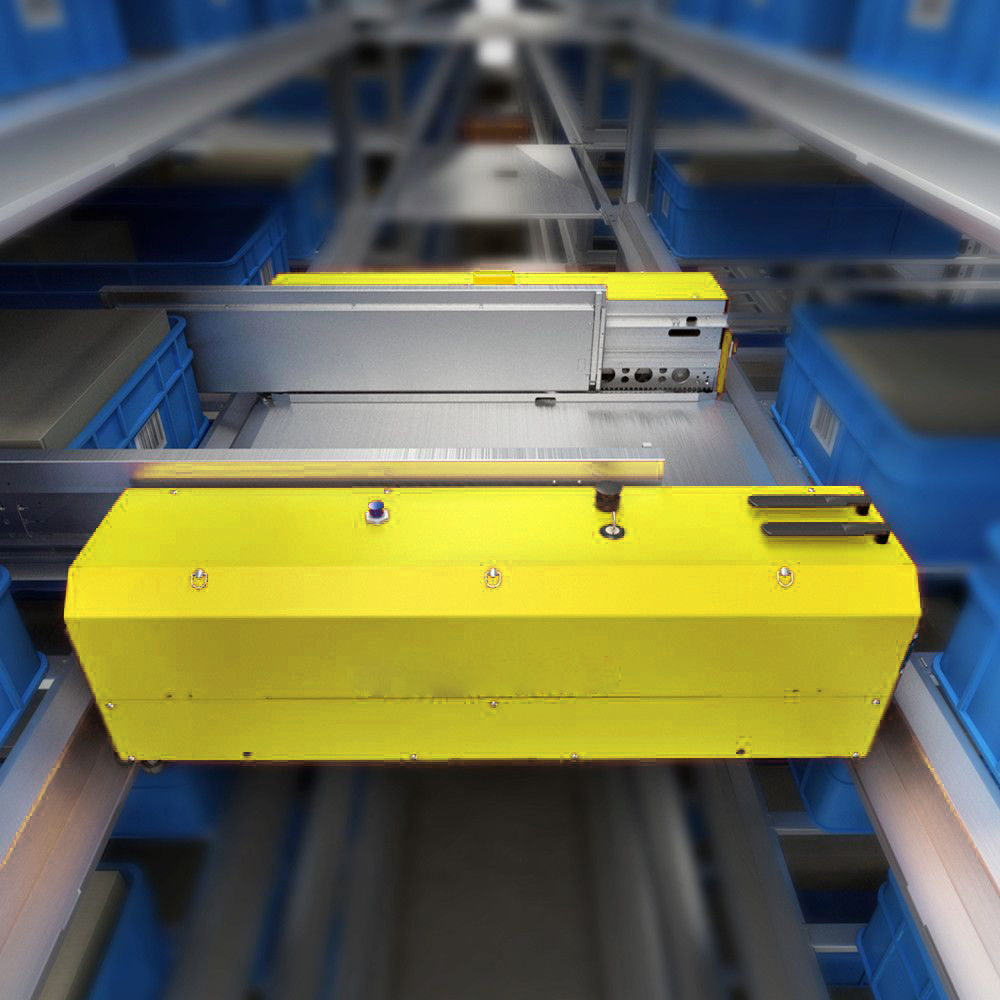

Core Technical Capabilities

- Intelligent Collaboration:Cluster scheduling via WMS/WCS integration (parent-child vehicle coordination & stacker-RGV linkage).

- Precision & Safety:Laser positioning (±2mm) + LIDAR/ultrasonic obstacle detection (<10cm emergency stop distance).

- Omnidirectional Mobility:4-way movement (X/Y/Z-axis) with lane switching & multi-floor operation (slope climbing ≤5°), eliminating fixed-path constraints.

- Flexible Payload Transfer:Roller/lifting/fork interfaces compatible with EUR/JIS pallets (adaptable to floor tracks or rack rails).

Competitive Advantages

- Operational Efficiency:2-3× throughput vs. drive-in racks; 80% vertical space utilization.

Scalable Intelligence:AI-optimized routing & predictive maintenance; expandable to AGV/AMR fleets. - Environmental Adaptability:Low-temperature lithium batteries (-25℃); IP54-rated components for humid/cleanroom environments.

- Reliability:Tier-1 components (e.g., German Rexroth drives); triple safety redundancy (collision/overload/low-battery alerts).

Specifications

| Parameter | Specification |

|---|---|

| Payload Capacity | Light (0.5-1T), Medium (1-2T), Heavy (2-5T) |

| Speed | 1.4m/s (unloaded), 1.1m/s (loaded) |

| Navigation | Laser SLAM (±2mm) / RFID track guidance |

| Battery & Charging | 48V LiFePO₄ (7h runtime); 3.5h fast charge/swappable |

| Operating Temp. | Standard (0°C to 50°C), Cryogenic (-25°C to 40°C) |